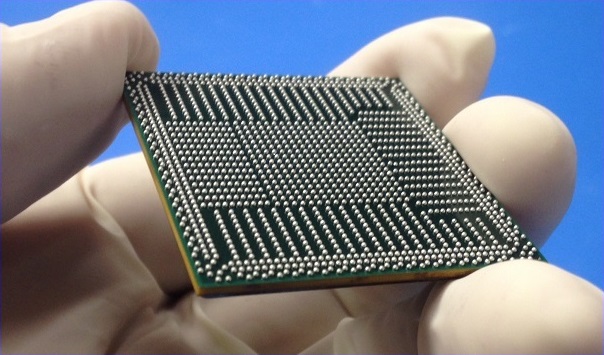

QCG employs process engineers with extensive BGA Reball and BGA Rework experience with both lead free (Pb-free) and leaded processes.

PDR Infrared BGA Rework Station

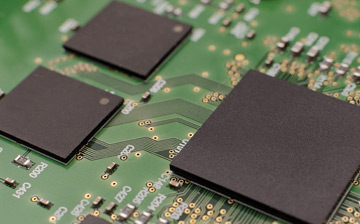

The system is tool free, gas free, instantly/precisely controllable with digital laser thermal couples to provide real-time instant and precise control to mitigate thermal shock. The system produces 100% yield BGA rework without any complications. It provides the extremely high levels of profiling and process control necessary for the effective rework of even the most advanced packages, including SMDs, BGAs, CSPs, QFNs, Flip chips. Excellent for rework down to 0201 and lead-free applications.

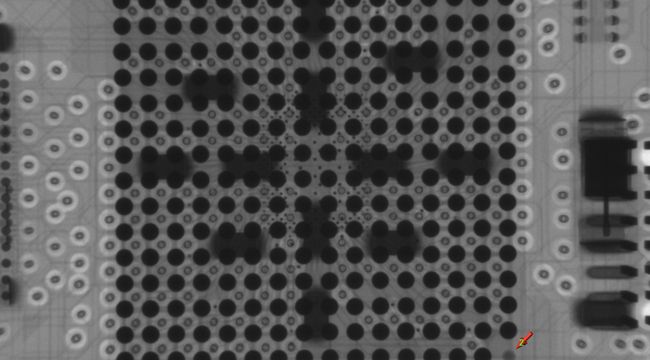

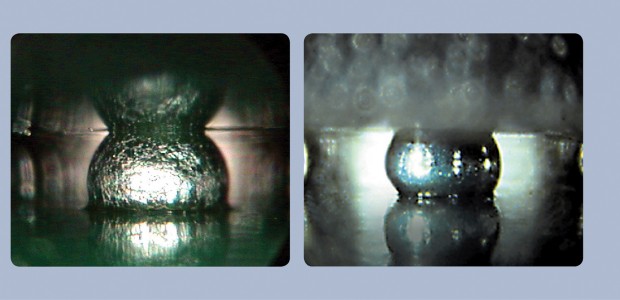

Ersascope Inspection

In addition to Xray, Ersascope provides 7 axis magnified 90 degree visual inspection for solder joints on BGA, uBGA, CSP, Flip-chip, CGA and THT connections.

If you need any help with the info above just click or call!

Click here for a BGA Quote